Commercialization: Ensuring the Quality

Models:

Models created for testing are I Profile Beams, of S Section, additionally weakened by circular holes (lightening holes) orderly positioned along the web. This type of beam elements is commonly used in engineering practice.

Material:

Material used for building this particular testing models is PLA (Polylactic Acid).

There are ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid) FDM filaments. The material is sold in coils or spool; they look like heavy-duty fishing line.

PLA is made from plant-based materials, so there’s less fumes to contend with if you’re working in an enclosed space. ABS is oil-based, so there is a noticeable – and sometimes strong, depending on how long the printer is running – petroleum smell.

Both PLA and ABS are sandable, paintable, and bondable. Finer detail can be extracted from PLA, but this material can tend toward brittleness and floppy, curled edges. While you don’t need to have a heated printer bed to use PLA, it does benefit from one. A cooling process is also required.

ABS is a bit more flexible, and it does not require a cooling process. However it may crack or warp if you’re not careful about the structure of your object. ABS has a higher melting temperature, and it needs polyimide tape for best adherence.

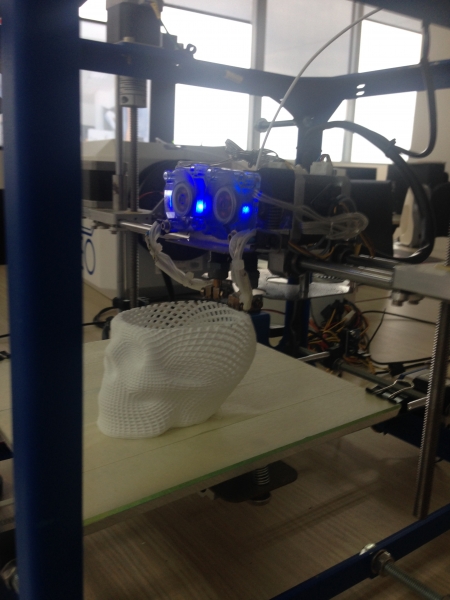

3D Printer:

The Neo 3D by German RepRap FDM printer.

Testing procedure:

Tests will be take place at ProDe laboratory on Shimadzu Universal EZ Testing Equipment, set to perform uniaxial-tension, uniaxial-compression and three-point-bending tests. The force set to be applied during the testing is up to 5KN. Software TrapesiumX, employed by Shimadzu, enables graphic interpretation of results obtained and real time graphic follow-up with observation of deformation.

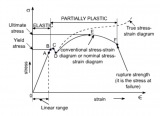

Interpretation of results:

To ensure the quality of interpreted results and to accurately define the range-of-use of the results obtained, set of experiments were performed ahead of the main testing;

1) Static three-point-bending test of two types of brittle materials ( glass and chock ). These tests provided us with limits and shape of sigma- epsilon curve, characteristic for brittle failure.

2) Static and cyclic load three-point-bending test of ductile material (perforated metal plates).

- Tested for cyclic load; Results with hysteretic curve and analysis of fatigue of materials.

- Tested for static load; Results with sigma-epsilon curve for ductile material.

Performed tests of brittle and ductile materials provided a good banchmarks for results obtained by testing of our main models, I profile beams made of PLA (Polylactic Acid) material.

Statistical results will be interpreted.

On a video clip listed below, please look at the frame on 57 seconds, capturing the brittle failure of a ceramic plate sample.